Lihlahisoa

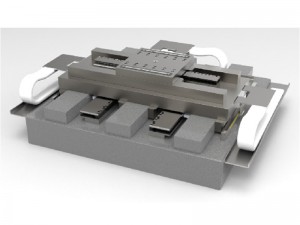

E-ABT-XY-360X360 (Ceramic linear motor stage) XY Air e behang Linear Motor Stage

● E loketse ho skena lits'ebetso kapa boemo bo nepahetseng haholo

● Kamore ea ho hloekisa e lumellana

● Mekhahlelo ea maeto ho ea ho 360 mm × 360 mm

● Bophahamo ba ho kenya 500 N

● Qeto ho 4.88nm kapa 1 nm, Velocity ho 500mm/s

● Sekhouto se ntseng se eketseha kapa sekhouto sa Absolute

● Liphetolelo tsa Alumina ceramic li fumaneha, thepa e fanang ka ho nepahala le ts'ebetso e phahameng ka ho fetisisa, empa ka theko e phahameng.

Lisebelisoa le likhetho

● Sefe le Lisebelisoa tsa ho Lokisetsa Moea

● Lilepe tse eketsehileng

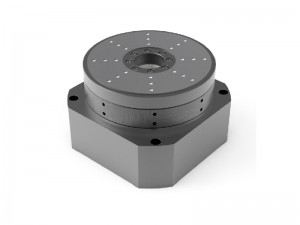

● Metheo ea mochini

● Lipoleiti tsa motheo tse entsoeng ka granite le mekhoa ea ho fokotsa ho sisinyeha

● Litumellano tse loketseng bakeng sa li-positioner tse ling tse kang tip/tilt platforms kapa 6-axis positioners tse nang le li-piezo drive.

Libaka tsa kopo

Sistimi ea ho beha maemo e loketse lits'ebetso tse ngata tsa boemo bo holimo, joalo ka metrology, photonics, le scanning e nepahetseng hammoho le tlhahiso ea li-semiconductor kapa tse bataletseng.

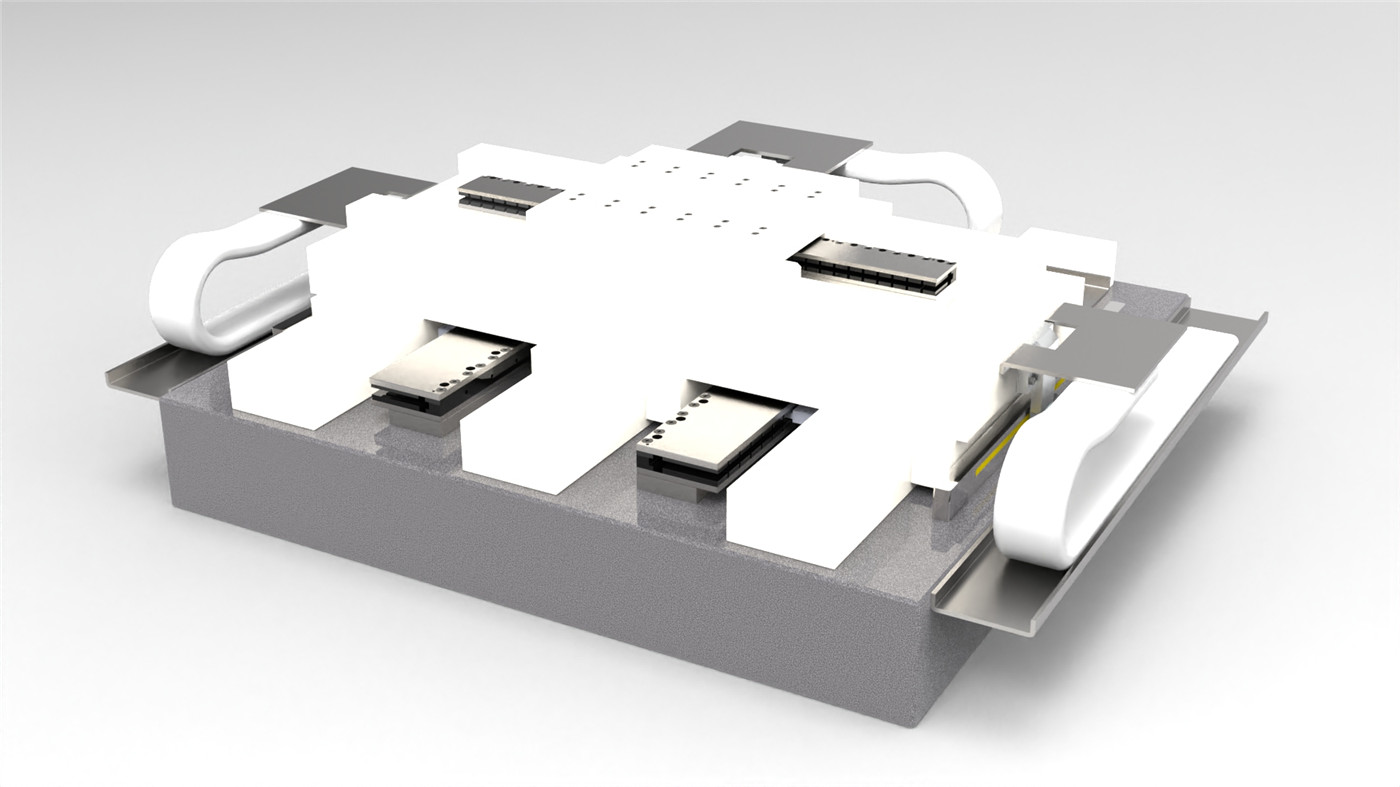

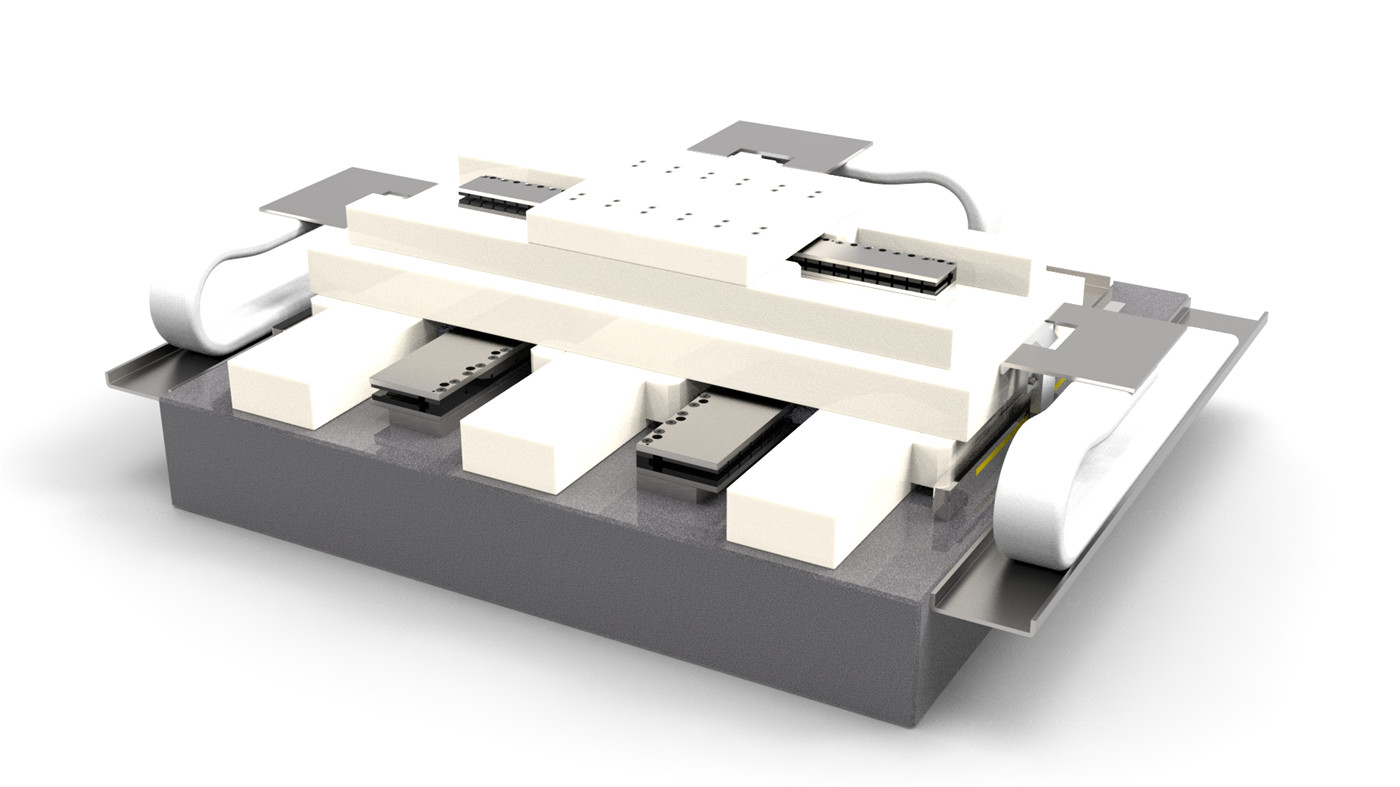

Nako e telele ea bophelo, likamore tse hloekileng tse tsamaisanang le liketane tsa ho hula

E-ABT-XY-360X360 e na le likhoele tsa ribone tsa boleng bo holimo, tse tšoarellang nako e telele le li-hoses tsa moea.Patlisiso e batsi le nts'etsopele e entse hore ho be le sistimi e ntlafalitsoeng ea taolo ea li-cable e nolofalletsang limilione tsa lipotoloho tse sa hlokeng tlhokomelo.Ho roala ha Teflon ho tiisa sebopeho sa likaroloana tse tlase

Ka lebaka la motsamao o senang likhohlano, ha ho na likaroloana tse entsoeng, tse etsang hore methati ea PIglide e be e loketseng lits'ebetso tsa kamore ea ho hloekisa.

| Tlhaloso | Lintho tse tloaelehileng | Lintho tse entsoeng ka ceramic |

| Mofuta oa koloi | Enjene ea mantlha ea mekhahlelo e meraro | |

| Qeto ea Opticval Encode | sincos 4.88nm (liqeto tse ling tse phahameng ke tsa boikhethelo) | |

| X axes Motor thrust[N] | Tlhōrō e tsoelang pele ea 90N 315N | |

| Y axes Motor thrust[N] | E tsoelang pele 219N*2 Peak 750N*2 | |

| X lilepe Ho potlakisa moroalo[g] | 4.5G | |

| Y axes No-load acceleration[g] | 3G | |

| Mohato o monyane[nm] | 10nm (e nang le nanopwm kapa mokhanni oa mohala) | |

| Tsamaea [mm] | 360×360 | |

| Ho nepahala ha Pheta-pheta [um] | ±0.15 | ±0.1 |

| Ho nepahala [um] | ±0.5 | ±0.3 |

| Flatness [um] | ±1 | ±0.5 |

| Ho otloloha [um] | 1.5 | 1 |

| Lebelo le Leholo [mm/s] | 500mm/s | |

| Mojaro o Moholo [kg] | 50kg | |

1) "Nanopositioning" ke eng?

K: Nakong e fetileng, mohatla o nepahetseng oa mohatla oa mohatla o ikemetseng o ne o atisa ho bitsoa karolo ea "micropositioning" ea 'maraka.Lentsoe "microposition" le tsoa 'neteng ea hore litsamaiso tsa boemo bo holimo tse nepahetseng li ne li sebetsa khafetsa maemong a micron.Baetsi sebakeng sena ba ne ba hlakisa litšobotsi tsa bohlokoa tsa sistimi joalo ka ho pheta-pheta ha Bi-directional, Ho nepahala, le Botsitso ka likarolo tsa li-micron.Litsamaiso tse joalo li ile tsa tlatsa litlhoko tsa indasteri ka ho lekaneng ho tloha ho Life Science le Diagnostics, ho ea ho Non-contact metrology, ho ea makaleng a Tech a Semiconductor, Data Storage, le Flat Panel Display.

Ka pele ho fihlela mehleng ea rona ea kajeno 'me litsamaiso tse joalo ha li sa lekana.Indasteri e ntseng e tsoela pele e hloka litlhoko tsa microscopy le biotechnology e ntlafatsang maemo a ts'ebetso ho tsoa ho baetsi ba lisebelisoa tsa boemo bo nepahetseng.Ha likarolo tsa thahasello limmarakeng li ntse li fokotseha, bokhoni ba ho ema boemong ba nanometer bo fetoha bohlokoa ba 'maraka.

2) Na sehlahisoa sa hau se tsamaea ka sekepe mose ho maoatle?

A: E, re romela lihlahisoa tsa rona linaheng tse ling 'me re na le barekisi libakeng tse khethiloeng.

3) Ke kopa qotsa sehlahisoa se itseng joang?

A: O ka romela lengolo-tsoibila ho rona, re tla etsa khotheishene ea molao ho uena.

4) Na lihlahisoa li ka khoneha?

A: We fana ka tharollo ea mantlha ea motsamao bakeng sa bareki ba rona.Maemong a mangata sena se kenyelletsa ho etsa kapa ho hlophisa lihlahisoa tsa rona tse tloaelehileng ho latela ts'ebeliso e ikhethang ea moreki le litlhaloso.Ka kopo ikopanye le rona haeba u thahasella ho etsa kapa ho lokisa e 'ngoe ea lihlahisoa tsa rona tse tloaelehileng, kapa haeba u ka rata ho sebetsa le sehlopha sa rona sa boenjiniere ho rala tharollo e ikhethang ho khotsofatsa litlhoko tsa hau tsa mohloli oa maikutlo.Haeba lebelo lena le fetisitsoe, ho qalisoa ha lipalangoang ha ho sa sebetsa, 'me phallo e tlameha ho nchafatsoa.

5)Mekhahlelo ea gantry ke eng?

A: Mekhahlelo ea gantry e etselitsoe ho fana ka phetisetso e ke keng ea lekanngoa le ts'ebetso e ntle haholo tlasa maemo a nnete a ts'ebetso ea lefats'e.Mekhahlelo ea rona ea gantry e etselitsoe ho tsamaisa lintho tse kang lik'hamera tsa tlhahlobo, lihlooho tsa laser, kapa lisebelisoa tse khethehileng tsa bareki holim'a li-substrates tse ka tlosoang kapa lisebelisoa tse behiloeng motheong oa sistimi.Setsi sa gantry se ka fanoa ka masoba a ntseng a eketseha bakeng sa ho kopanya hardware ea moreki ho ea sethaleng.Ka lebaka la bonolo le bonolo ba ho bokana, ke tlhophiso e loketseng ea sethala sa gantry bakeng sa OEMS le mochini oa ho haha li-system integrators bakeng sa likopo tse hlokang.Bongata ba lihlahisoa tse tloaelehileng tsa "screw driven" tsa "Dover Motion" le "servo motor linear" li ka kopanngoa hammoho e le sethala sa gantry ho fihlela ts'ebetso e nepahetseng le maeto bakeng sa motsamao oa XYZ.

● Motheo o hlophisitsoeng esale pele bakeng sa boiketlo ba ho kopanya;

● Risers ho fana ka sebaka pakeng tsa botlaaseng le ho tsamaea beam;

● Lipina tsa cable tse kopantsoeng le hi flex cable;

● Lilepe tsohle li lekoa hammoho 'me tsa chesoa ho netefatsa hore litlhoko tsa ts'ebetso le ts'epo lia fihlelleha pele li romelloa.