Lihlahisoa

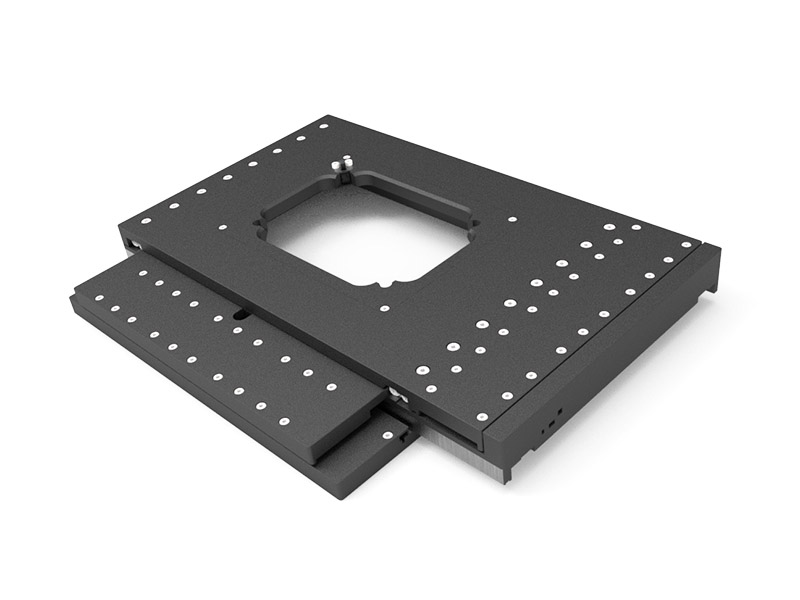

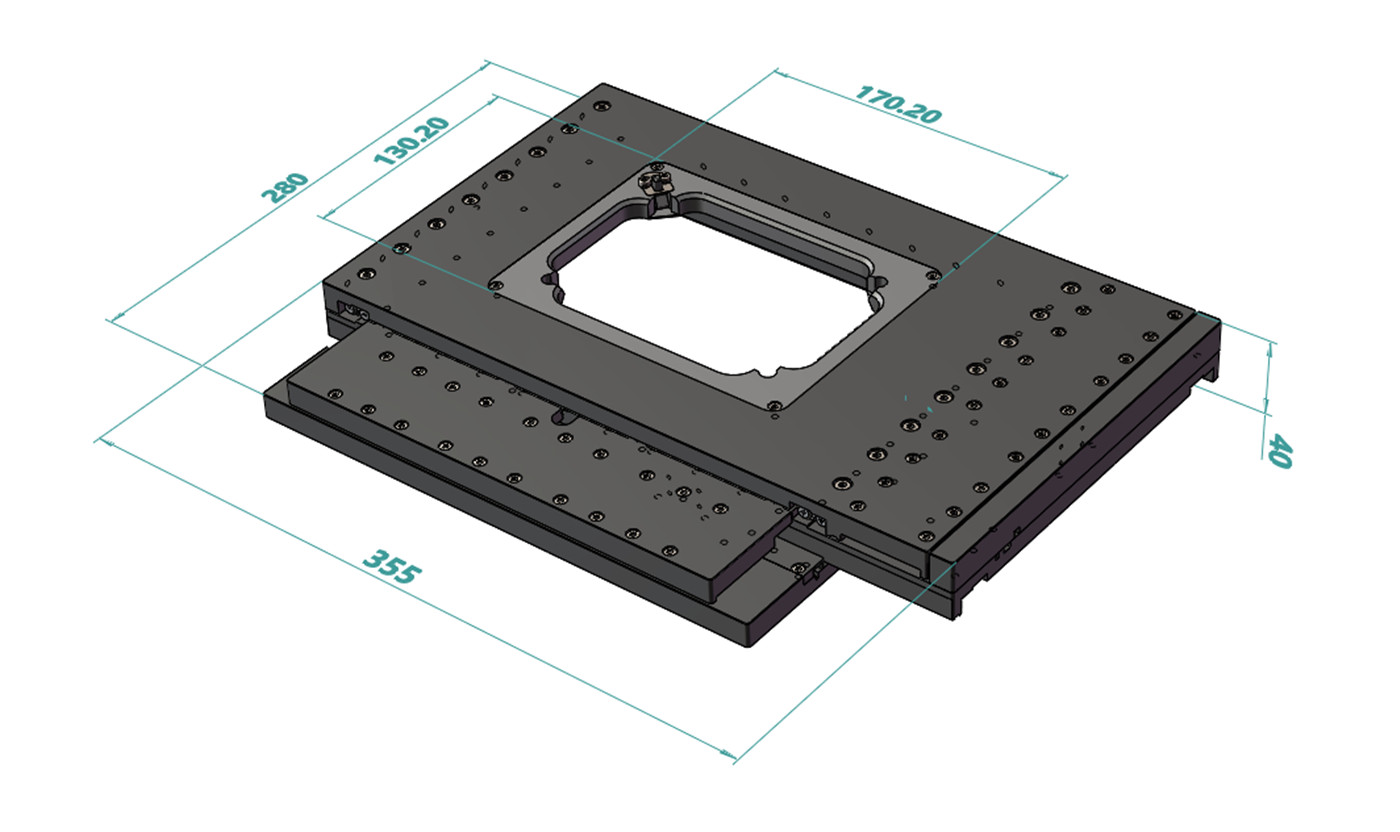

E-EMSLM-120X100-INXY-E50 Moekoskoupo e Inverted Linear Motor Stage

Litekanyo tse ka sehloohong le liparamente tsa ts'ebetso:

● Stroke: 120mm x 100mm

● Qeto ea grating: 50nm

●Bonyane mohato oa boholo: 100nm

● Pheta ho nepahala ha boemo: ≤± 250nm

● Lebelo le phahameng ka ho fetisisa: ≥300mm / s

● Mofuta oa terene: tataiso ea cross roller

●Moroalo o moholo: ≥5kg

● Mochine oa ho khanna ka ho toba, ha ho na morao

● Lintho tse ka sehloohong: Aviation grade aluminium alloy

● Phekolo ea holim'a metsi: sandblasting le hard anodic oxidation holim'a tafole e ka holimo e thellang, 'me likarolo tse ling tsa sebopeho hangata li na le anodized.

Melao ea ho reha mabitso a Mohlala oa Sehlahisoa

MSLM - 120X100 - INXY - E50

○1 ○2 ○3 4○

○1 MSLM ke khutsufatso ea Senyesemane ea Linear Motor Microscope Platform

○2.

○3 XY e emela tataiso le mofuta oa axis e sebetsang, 'me tataiso ea kamehla e tiisitsoe ho latela tsamaiso ea Cartesian coordinate

○4 E50 e emela tharollo ea mofuta ona oa grating ea sehlahisoa, yuniti ke nm, tharollo ea kamehla ea sehlahisoa ke 50nm, khetho ea 20nm\100nm\0.5um\1um\5um joalo-joalo. Liphetoho tsa tharollo li tla lebisa liphetohong tsa lebelo le phahameng la sethaleng le ho pheta ho nepahala ha boemo.Ka kopo ikopanye le moetsi bakeng sa lintlha.

Lintho tsa Tlhokomelo e Khethehileng

1. The linear motor platform is a high-precision precision equipment, kahoo haeba u batla ho fumana tshebetso e ntle ka ho fetisisa, u lokela ho etsa bonnete ba hore ho na le sebaka se lekaneng sa ts'ebetso, haholo-holo ho lisebelisoa tsa On lisebelisoa tse hlokang ho nepahala ha boemo bo ka tlase ho 1um, tlhahiso ea matšoao ohle a hloka ho kopana le mocheso o itseng, mongobo, khatello ea moea, vibrate, joalo-joalo. Bakeng sa litlhoko tse qaqileng, ka kopo ikopanye le moetsi bakeng sa lipuisano tse eketsehileng le puisano.

2. Li-platform tsohle li ka laeloa ka thoko.Haeba litlhoko tsa ho nepahala le ts'ebetso ea thepa li phahame, ho khothalletsoa ho sebelisa letoto la taolo ea MCS le hlahisoang ke rona.Lihlahisoa tse rometsoeng ke balaoli ba letoto la MCS li tla ntlafatsoa le ho lokisoa tlhahlobong ea feme, e leng khetho ea hau ea pele bakeng sa tšebeliso e batloang haholo.

1) "Nanopositioning" ke eng?

K: Nakong e fetileng, mohatla o nepahetseng oa mohatla oa mohatla o ikemetseng o ne o atisa ho bitsoa karolo ea "micropositioning" ea 'maraka.Lentsoe "microposition" le tsoa 'neteng ea hore litsamaiso tsa boemo bo holimo tse nepahetseng li ne li sebetsa khafetsa maemong a micron.Baetsi sebakeng sena ba ne ba hlakisa litšobotsi tsa bohlokoa tsa sistimi joalo ka ho pheta-pheta ha Bi-directional, Ho nepahala, le Botsitso ka likarolo tsa li-micron.Litsamaiso tse joalo li ile tsa tlatsa litlhoko tsa indasteri ka ho lekaneng ho tloha ho Life Science le Diagnostics, ho ea ho Non-contact metrology, ho ea makaleng a Tech a Semiconductor, Data Storage, le Flat Panel Display.

Ka pele ho fihlela mehleng ea rona ea kajeno 'me litsamaiso tse joalo ha li sa lekana.Indasteri e ntseng e tsoela pele e hloka litlhoko tsa microscopy le biotechnology e ntlafatsang maemo a ts'ebetso ho tsoa ho baetsi ba lisebelisoa tsa boemo bo nepahetseng.Ha likarolo tsa thahasello limmarakeng li ntse li fokotseha, bokhoni ba ho ema boemong ba nanometer bo fetoha bohlokoa ba 'maraka.

2) Na sehlahisoa sa hau se tsamaea ka sekepe mose ho maoatle?

A: E, re romela lihlahisoa tsa rona linaheng tse ling 'me re na le barekisi libakeng tse khethiloeng.

3) Ke kopa qotsa sehlahisoa se itseng joang?

A: O ka romela lengolo-tsoibila ho rona, re tla etsa khotheishene ea molao ho uena.

4) Na lihlahisoa li ka khoneha?

A: Re fana ka litharollo tsa mantlha tsa motsamao o hlophisitsoeng bakeng sa bareki ba rona.Maemong a mangata sena se kenyelletsa ho etsa kapa ho hlophisa lihlahisoa tsa rona tse tloaelehileng ho latela ts'ebeliso e ikhethang ea moreki le litlhaloso.Ka kopo ikopanye le rona haeba u thahasella ho etsa kapa ho lokisa e 'ngoe ea lihlahisoa tsa rona tse tloaelehileng, kapa haeba u ka rata ho sebetsa le sehlopha sa rona sa boenjiniere ho rala tharollo e ikhethang ho khotsofatsa litlhoko tsa hau tsa mohloli oa maikutlo.Haeba lebelo lena le fetisitsoe, ho qalisoa ha lipalangoang ha ho sa sebetsa, 'me phallo e tlameha ho nchafatsoa.

5) Gantry ke engkgamaes?

A: Mekhahlelo ea gantry e etselitsoe ho fana ka phetisetso e ke keng ea lekanngoa le ts'ebetso e ntle haholo tlasa maemo a nnete a ts'ebetso ea lefats'e.Mekhahlelo ea rona ea gantry e etselitsoe ho tsamaisa lintho tse kang lik'hamera tsa tlhahlobo, lihlooho tsa laser, kapa lisebelisoa tse khethehileng tsa bareki holim'a li-substrates tse ka tlosoang kapa lisebelisoa tse behiloeng motheong oa sistimi.Setsi sa gantry se ka fanoa ka masoba a ntseng a eketseha bakeng sa ho kopanya hardware ea moreki ho ea sethaleng.Ka lebaka la bonolo le bonolo ba ho bokana, ke tlhophiso e loketseng ea sethala sa gantry bakeng sa OEMS le mochini oa ho haha li-system integrators bakeng sa likopo tse hlokang.Bongata ba lihlahisoa tse tloaelehileng tsa "screw driven" tsa "Dover Motion" le "servo motor linear" li ka kopanngoa hammoho e le sethala sa gantry ho fihlela ts'ebetso e nepahetseng le maeto bakeng sa motsamao oa XYZ.

● Motheo o hlophisitsoeng esale pele bakeng sa boiketlo ba ho kopanya;

● Risers ho fana ka sebaka pakeng tsa botlaaseng le ho tsamaea beam;

● Lipina tsa cable tse kopantsoeng le hi flex cable;

● Lilepe tsohle li lekoa hammoho le ho chesoa ho netefatsa hore litlhoko tsa ts'ebetso le ts'epo lia fihlelleha pele li romelloa;