Litsamaiso tse tsamaeang ka mela - tse nang le setsi kapa matlo, sistimi e tataisang, le mochini oa ho khanna - li fumaneha ka mefuta e fapaneng ea meralo le litlhophiso ho lumellana le ts'ebeliso efe kapa efe.'Me kaha liqapi tsa tsona li fapane haholo, hangata li aroloa ho latela melao-motheo ea kaho le ea ts'ebetso.Taba ea bohlokoa: Lentsoe "actuator" ka tloaelo le bolela tsamaiso e tsamaeang ka mela e nang le ntlo ea aluminium e kentseng tataiso le mekhoa ea ho khanna;litsamaiso tse bitsoang "tafole," kapa "litafole tsa XY," hangata li entsoe ka letlapa le bataletseng leo likarolo tsa tataiso le koloi li kenngoeng ho tsona;le "linear stage" kapa "linear translation stage" hangata e bolela mokhoa o ts'oanang kaho oa tafole ea linear empa o etselitsoe ho fokotsa liphoso tsa ho beha maemo le maeto.

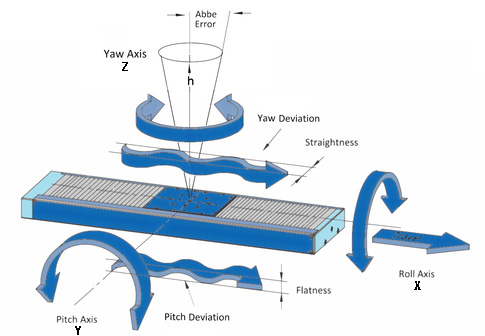

Litsamaiso tsa motsamao oa linear li ka bonts'a mefuta e meraro ea liphoso: liphoso tsa mela, liphoso tsa angular, le liphoso tsa polane.

Liphoso tsa Linear ke liphoso tsa ho beha ho nepahala le ho pheta-pheta, tse amang bokhoni ba sistimi ea ho fihlela boemo bo lakatsehang.

Liphoso tsa angular - tse atisang ho bitsoa roll, pitch, le yaw - li kenyelletsa ho potoloha ka lilepe tsa X, Y, le Z, ka ho latellana.Liphoso tsa angular li ka lebisa ho liphoso tsa Abbé, e leng liphoso tsa angular tse matlafalitsoeng ke bohōle, joalo ka sebaka se pakeng tsa tataiso ea mela (mohloli oa phoso ea angular) le ntlha ea sesebelisoa sa sesebelisoa sa ho lekanya.Ke habohlokoa ho hlokomela hore liphoso tsa angular li teng le ha sethala se sa tsamaee, kahoo li ka ba le phello e mpe lits'ebetsong tse tsitsitseng tse kang ho lekanya kapa ho tsepamisa maikutlo.

Liphoso tsa Planar li etsahala ka mahlakoreng a mabeli - ho kheloha leetong la sefofane se rapameng, se boleloang e le ho otloloha, le ho kheloha ha maeto ka sefofane se otlolohileng, se bitsoang flatness.

Leha ho se na melao kapa litataiso tse tiileng mabapi le se bopiloeng ke sethala, li tsejoa ka bophara e le sehlopha se nepahetseng ka ho fetesisa sa metsamao ea metsamao.Ha sistimi e bitsoa sethala sa mola, ho utloisisoa ka kakaretso hore sistimi e ke ke ea fana feela ka ho nepahala ha boemo bo holimo le ho pheta-pheta, empa le liphoso tse tlase tsa angular le polane.E le ho finyella boemo bona ba ts'ebetso, ho na le melao-motheo e 'maloa eo bahlahisi ba e latelang ka kakaretso mabapi le kaho le mofuta oa likarolo tse sebelisoang moahong oa sethala.

Mokhahlelo ona o otlolohileng o sebelisa li-bearings tsa profil tse recirculating tse nang le mola oa koloi.

Taba ea pele, ho fapana le litsamaiso tse ling tse tsamaeang ka mela, tse tloaetseng ho sebelisa aluminium extrusion kapa poleiti joalo ka motheo, sethala sa mela e qala ka motheo o nepahetseng oa fatše.Mekhahlelo e etselitsoeng maemo a phahameng ka ho fetisisa a ho bata, ho otloloha, le ho tiea hangata ho sebelisoa motheo o entsoeng ka tšepe kapa granite, le hoja aluminium e sebelisoa mekhoeng e meng.Litšepe le granite li boetse li na le li-coefficients tse tlase tsa katoloso ea mocheso ho feta aluminium, kahoo li bonts'a botsitso bo betere maemong a nang le mocheso o feteletseng kapa o fapaneng.

Sistimi ea litataiso e boetse e kenya letsoho ho otloloheng le ho batang ha maeto, kahoo mekhoa ea tataiso bakeng sa sethala se melang ke liporo tse hlakileng haholo,li-slide tse tšetsoeng, kapadibering tsa moya.Litsamaiso tsena tsa tataiso li fana ka ts'ehetso e thata haholo ho fokotsa liphoso tsa angular, tse ka lebisang ho liphoso tsa Abbé ha ho e-na le phoso pakeng tsa tšimoloho ea phoso (tataiso) le ntlha ea thahasello (sebaka sa lisebelisoa kapa boemo ba mojaro).

Le ha mefuta e mengata ea litsamaiso tse tsamaeang ka mela e sebelisa mekhoa e metle haholo ea ho khanna, methati ea mela e sebelisa e 'ngoe ea mahlale a mabeli haholo: sekoti sa bolo se nepahetseng haholo kapa enjene ea mola.Li-motor tsa Linear hangata li fana ka boemo bo phahameng ka ho fetisisa ba boemo bo nepahetseng le bo pheta-phetoang, kaha li felisa ho latela melao le ho khutlela morao ka har'a mochini oa koloi le ho hokahana lipakeng tsa koloi le koloi.Bakeng sa boemo bo khethehileng ba mesebetsi ea ho beha li-sub-micron,li-activators tsa piezokapali-motors tsa coil tsa lentsoehangata ke mekhoa ea khetho ea ho khanna, bakeng sa motsamao oa bona o nepahetseng haholo, o phetoang.

Leha lentsoe "linear stage" le bolela tsamaiso e le 'ngoe ea axis, mekhahlelo e ka kopanngoa ho theha litsamaiso tse ngata tse kang mekhahlelo ea XY,methati e hlophisitsoeng, le mekhahlelo ea gantry.

Sethala sena sa li-axis tse peli se sebelisa li-air bearing le li-motor tse melang holim'a motheo oa ceramic.

Mokoloto oa setšoantšo: Aerotech

Nako ea poso: Mar-29-2023